Vous êtes intéressé par ce système ?

Curabitur vulputate arcu odio, ac facilisis diam accumsan ut. Ut imperdiet et leo in vulputate.

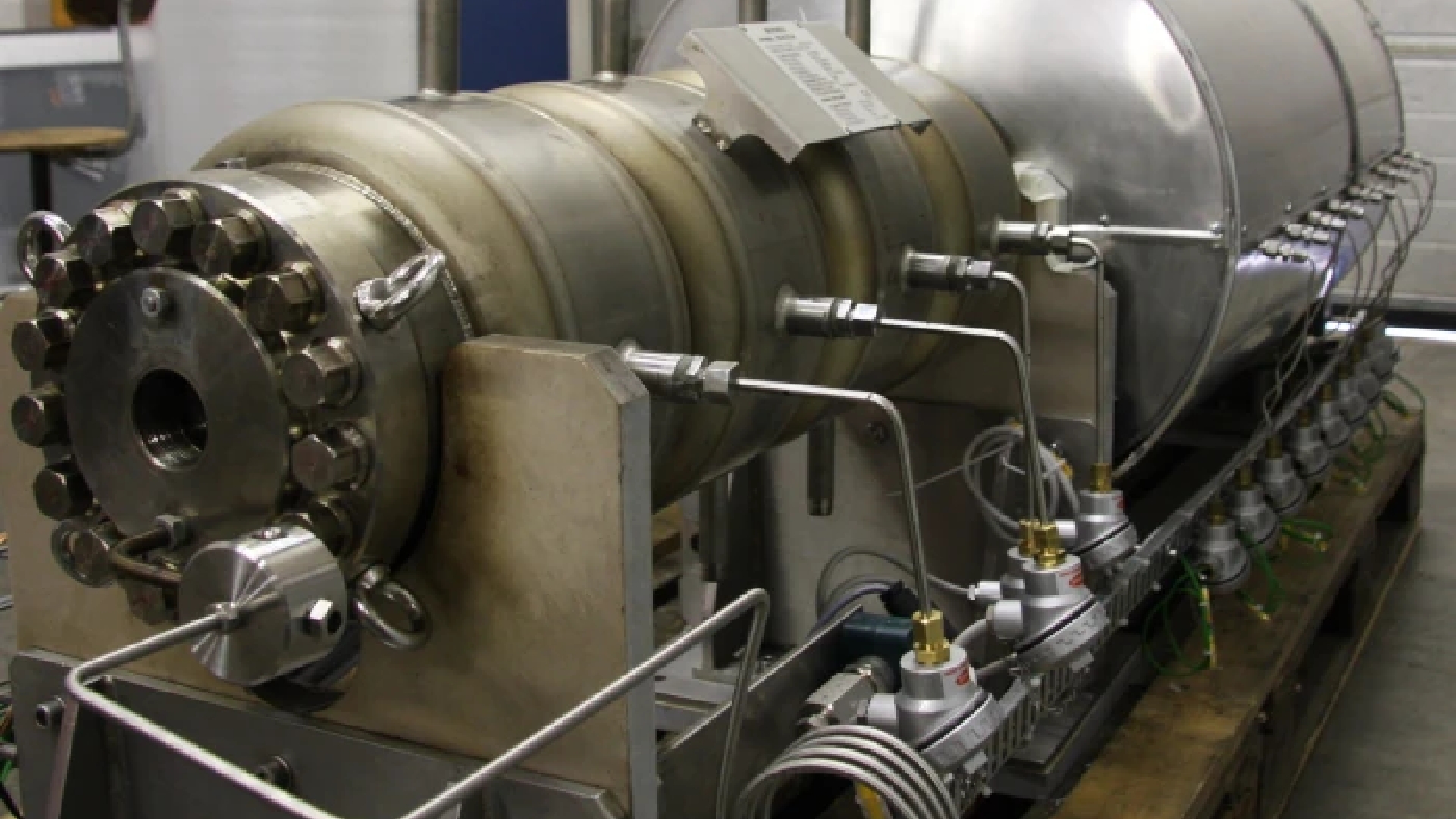

Our laboratory extraction equipment using supercritical CO2 as a solvent is also compatible with the use of subcritical water. Kept liquid despite a temperature above 100°C by an increase in its pressure, the so-called subcritical water sees its solvent properties modified. Weakly polar compounds thus become soluble in water.

This process allows:

For larger applications, our equipment is developed specifically for this process.

| Volume | 400L 2 x 400L |

| Flow | 2500 kg/h at 400 bar 1500 kg/h at 1000 bar |

| Pressure | 400 bar 700 bar 1000 bar |

| Temperature | 0 - 100 °C |

| Fonctionnalité | Reduced CO2 consumption thanks to the recycling line |

| Norme | PED 2014/68/UE |

| Alimentation | 400 V - 50 Hz - 3 phases + earth / 32A |

Co-solvent pump

3rd separator (cold trap)

3rd extractor to increase extraction capacity

Liquid Fractionation Column

cGMP

Software update (pharmaceutical grade: 21 CFR Part 11)

Supercritical CO2 fractionation allows the extraction of liquid biomass in a countercurrent fractionation column. This method is used either for the separation of molecules from a complex mixture or for purification after supercritical CO2 extraction.

In addition to supercritical CO2 extraction, this green process has the advantage of precisely separating the molecules of interest or target compounds to obtain different extract fractions while retaining their original properties and preserving sensitive compounds.

Fractionation takes place in a countercurrent column. CO2 is injected into an injector near the bottom of the column, with the feed being injected at several points. The light extract is recovered at the top of the column and the non-extracted part of the liquid (called raffinate) is recovered at the bottom.

The column is equipped with a heating system over the entire height of the column in order to carry out a temperature gradient fractionation, because the solubility of the compounds in supercritical CO2 decreases as the temperature increases. An extract reflux system increases the selectivity of the separation, since the extract is richer in the desired molecule.

Supercritical fractionation is used for formulation in cosmetics, for the creation of perfumes in perfumery or for the separation of EPA and DHA fatty acids from fish oil in the food industry.

The fractionation column can be coupled to equipment

The properties of CO2 are also used in powder production processes for the pharmaceutical, food and cosmetic industries.

Our equipment therefore allows the use of SAS (Supercritical Anti-Solvent), PGSS (Particle from Gas Saturated Solution) and RESS (Rapid Expansion of Supercritical Solution) processes.

These processes allow:

The use of CO2 thus makes it possible to produce powders at relatively low temperatures and by limiting the use of organic solvents.

Our SFP laboratory equipment makes it possible to simply combine these different processes.

Our production equipment is dedicated and optimized for your applications.

Curabitur vulputate arcu odio, ac facilisis diam accumsan ut. Ut imperdiet et leo in vulputate.